What is UV?

UV is abbreviation of Ultraviolet.

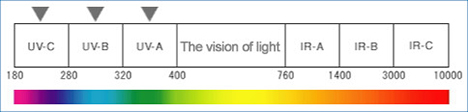

The industrial UV wavelength is between 200nm and 400nm.

We call the process to use UV-radiation to light up material to harden as UV cure.

What are UV-A、UV-B and UV-C?

The UV wavelength in the industrial is between 200 nm and 450 nm,

and we divided it into 3 parts:

1. UV-A: 320 - 390 nm

2. UV-B: 280 - 320 nm

3. UV-C : under 280 nm

What materials are used by UV curing?

UV cure for materials could be coating, inks, adhesives, lacquer,

and its components include:

1.Monomer

2.Hardener

3.Photoinitiator

4.Additive

5.Colors or dyestuff(inks)

Why we use the UV curing?

1.To decrease energy wasted.

2.Solvent cannot be evaporated and without air pollution.

3.Curtail produce time and increase efficiency.

What is the feature of high quality UV lamps?

1.Our UV lamps are highly ranked with unmatched reliability and conformity with certification of CE.

2.The life of our UV lamps is stable, and you don't need to interrupt your produce line to change it frequently.

3.Our UV lamps can be used at least 1000 hours continuously in normal environment.

Application of UV curing lamps

The physics feature s of materials are influenced by baker system.

No matter inks, lacquer and adhesives will depend on the design,

control method and parameter of UV lamp.

Four key parameters of UV lamp are:

1.Density of UV radiation — Density

2.UV spectral energy distribution — Wavelength

3.Intensity of UV radiation — Intensity

4.IR radiation

Whereas different materials demands different density, wavelength, intensity of UV radiation,

so the UV curing lamps can accelerate the production process and increase the output value.

English

English

繁體中文

繁體中文